SERVICES

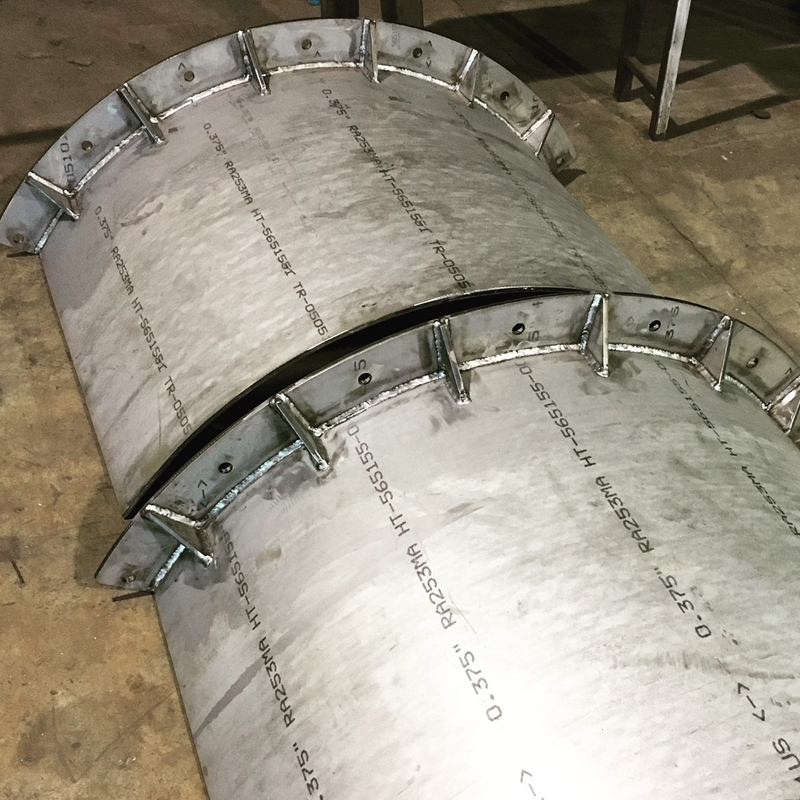

Welding & Fabrication

Our facility along with skilled welders carry “CWB certification.” We endeavour to keep our standards on safety, quality and capabilities at the highest levels; which allows us to provide the greatest possible product to our customers, always shipped in timely manner.

Fabrication of large and small projects is an additional expertise we are pleased to provide to complete our turn-key solutions. Additionally, our welding & fabrication projects typically comprise the use of the following metals:

- Aluminum

- Stainless

- Mild steel

- Wear plate

- Specialty alloys

3d printing (FDM)

We offer 3D Printing through fused deposition modeling (FDM) of plastic filament. This 3D Printer is a work horse – The Stratasys FORTUS 400MC 3D Production System. We further enhanced this system with an upgraded bed size of 16″ x 14″ x 16″ (406 x 355 x 406 mm) and dual build material canisters with dual support material canisters. We are ready and able to accept the most daunting of 3D print projects. Visit Stratasys to evaluate build material for your project. Materials we have on hand:

- ABS-M30

- PC-10 (poly-carb)

- Ultem 9085 resin

- FDM Nylon 12

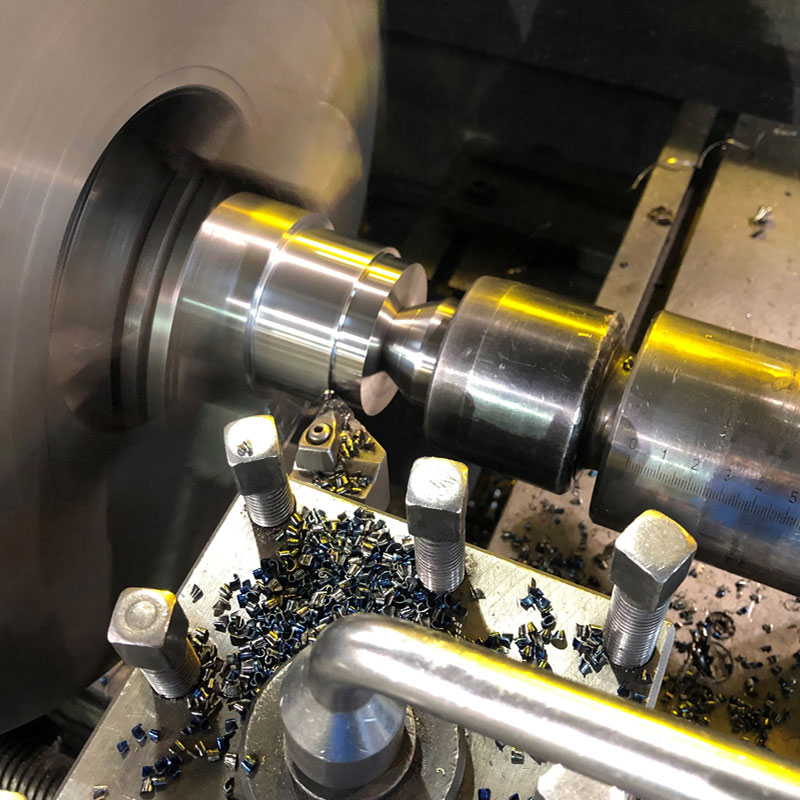

CNC Machining

- live tooling lathe with Y axis

- 2-axis lathe

- 4-axis milling machines

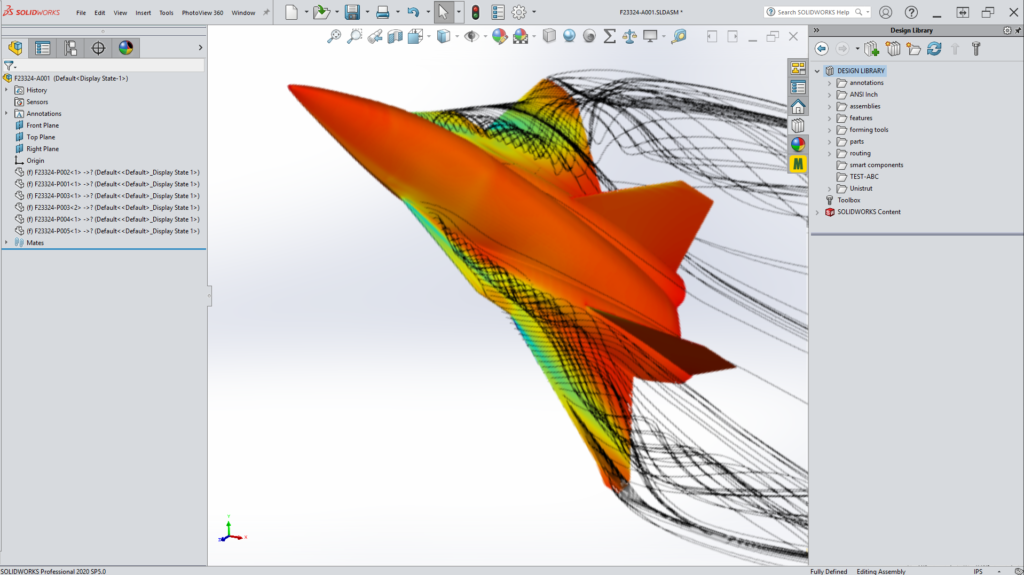

Computer Aided Design (CAD) & Drafting

Our dedicated drafting team will transform your thoughts, drawings or sketches into an accurate virtual 3D Part or Assembly model. This is where it all starts, with a powerful parametric 3D software “Solid Works” and a 2D advanced drafting program “AutoCAD” we can offer complete main stream services to meet your requirements.

Conventional Machining

Our machinists have the decades of know-how and right experience for all your conventional machining needs. From a unique “one-of” part all the way to simple or complicated repair work, we have you covered.

Powder Coating

The in-house powder coating department have the expertise and knowledge to make your products “shine, so to speak” as expected. We have a wide array of stock colours along with deep black and brilliant white to enhance and protect all your finishing needs.

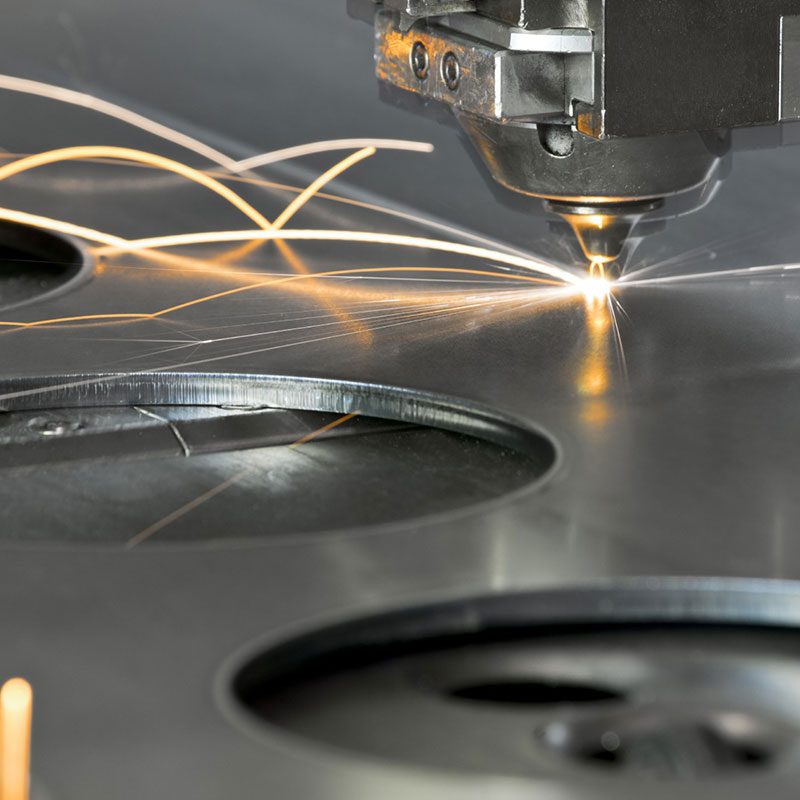

CNC Laser Cutting

With a large table capacity of 10ft x 5ft we can handle pretty much all the major precision cutting required. With great speed and accuracy capabilities our laser cutting jobs are dealt with efficiently so we can better deliver the final product.

Bending & Roll Forming

Our industrial sized bending and rolling machines can handle thin, small to heavy, large sheet and plate bending or rolling requirements.

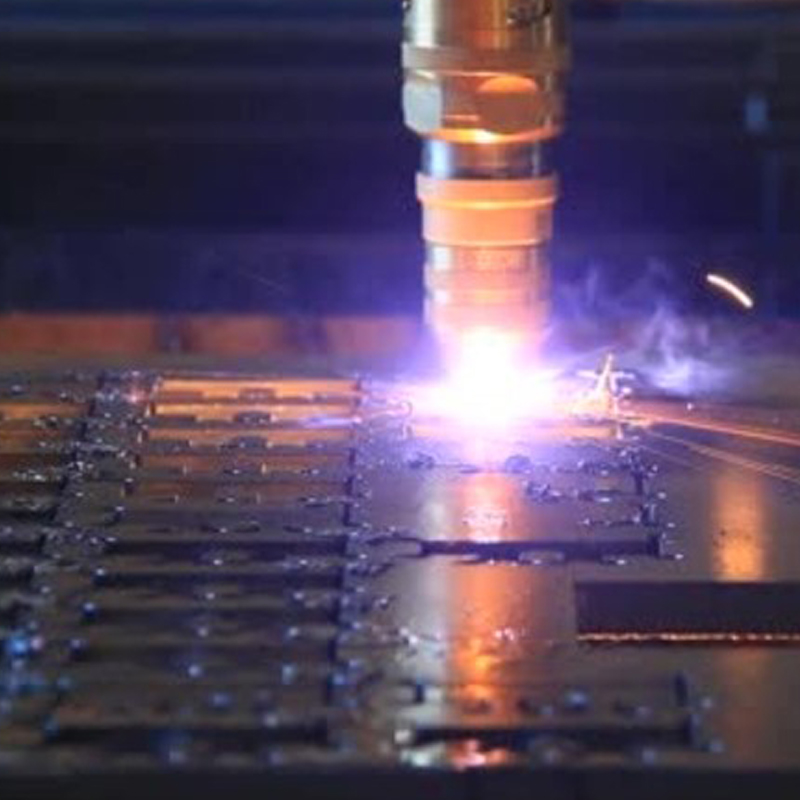

CNC Plasma Cutting

Plasma is one of many efficient methods of cutting metals when exact precision tolerances are not required. We will help you determine the best cutting scenario for your application. Along with our CAD team creating the right tool paths your product will emerge as required the first time.

Pipe Threading

Pipe threading is a demanding critical function of machining. We provide select services in this area for a few key industries such as Mining and Oil & Gas. We can handle the most challenging of tasks.

Raw Material Supply

Raw Material Supply is a key service some of our customers require. We can provide access to small and large qty units of specific materials or even to provide “pre-machining” cutting of blanks or sizing and stocking. Inquire how we can add this additional service to facilitate your orders.

Custom Manufacturing

A core service offered has always been our proficient abilities at turning around custom jobs of all shapes and sizes. Inquire with us today to see how we can assist.